Feb. 12, 2025

Currently, there are four primary processing methods for diamonds: thin film coated tools, thick film diamond welding tools, diamond sintered body tools, and single crystal diamond tools.

Thin film coated tools are created by depositing diamond thin films onto a rigid substrate with favorable thermal properties through chemical vapor deposition (CVD).

Materials such as Si3N4 ceramics, WC-Co cemented carbides, and metal W have thermal expansion coefficients closely matching that of diamond, resulting in minimal thermal stress during film formation. Thus, they serve well as base materials for tool bodies. However, in WC-Co cemented carbides, the presence of the cobalt bonding phase can lead to graphite formation between the diamond film and the substrate, compromising adhesion strength. To address this, pre-treatment is necessary to eliminate the Co influence, typically achieved through acid etching.

In the CVD process, a specific method activates gases containing carbon sources, allowing carbon atoms to deposit in a defined area under extremely low gas pressure. These carbon atoms crystallize into diamond during the condensation and deposition stages. Presently, the CVD techniques for diamond deposition include microwave, hot filament, and DC arc jet methods.

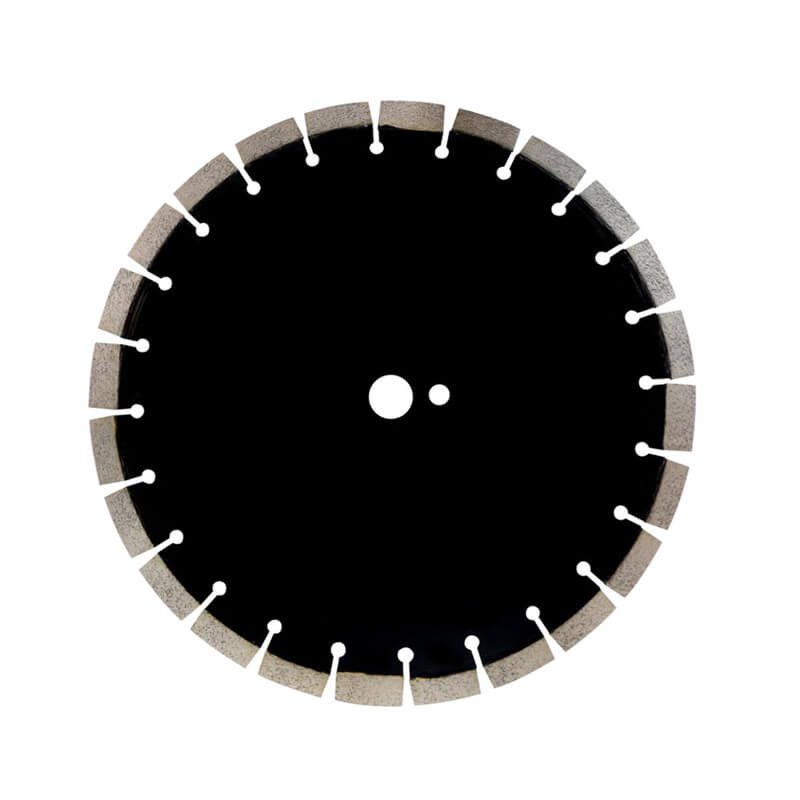

The primary benefit of diamond films is their versatility; they can be applied to various tools with intricate geometric configurations, such as diamond blades, end mills, reamers, and drill bits. These tools efficiently cut numerous non-metallic materials, demonstrating qualities like low cutting force, minimal deformation, stability during operation, slow wear rate, and reduced likelihood of workpiece deformation. This makes them suitable for fine processing tasks where precision and material integrity are crucial. Nevertheless, a major drawback is the poor adhesion between the diamond film and the substrate, along with the inability to re-sharpen diamond film tools.

The production of diamond thick film welding tools generally involves several steps: preparing large-area diamond films, cutting them into shapes and sizes suitable for tools, welding the diamond film to the substrate, and finishing the tool edges through grinding and polishing.

A commonly adopted process for fabricating diamond thick films is the DC plasma jet CVD method. Diamond is deposited on WC-Co alloy with a mirror finish. As the substrate cools, the diamond film may detach automatically. This approach boasts a rapid deposition speed (up to 930 μm/h) with tightly bonded lattice structures, although the growth surface can be relatively rough. Due to its high hardness, wear resistance, and non-conductivity, laser cutting is employed to shape the diamond thick films. This technique can operate in various environments, including air, oxygen, and argon, offering advantages such as narrow cutting seams and high efficiency.

Diamonds exhibit high interface energy with most metals and their alloys, hindering wetting by low-melting-point alloys. Thus, the weldability of diamonds is generally poor. Currently, enhancing diamond-metal weldability is achieved mainly by incorporating strong carbide-forming elements into copper-silver alloy solders or metallizing the diamond surface.

The solder typically consists of copper-silver alloy with titanium, welded in inert gas or vacuum without flux. A common composition is 68.8 wt% Ag, 26.7 wt% Cu, and 4.5 wt% Ti. Preparation techniques include arc melting and powder metallurgy. In this method, titanium reacts with carbon during welding to form titanium carbide (TiC), enhancing diamond and solder wetting and bonding strength. Heating usually occurs at 850 °C for 10 minutes, followed by slow cooling to reduce internal stress.

Surface metallization entails plating metal onto the diamond's surface through specialized treatment techniques, endowing it with metallic properties. Titanium is commonly used for plating, where it reacts with carbon to form TiC, known for good wettability and bonding strength with solder. Current titanium plating methods include vacuum physical vapor deposition (PVD), chemical vapor plating, and powder covering sintering. Notably, the PVD method has a low single-time coating amount, applying coating at temperatures below 500 °C, ensuring physical attachment rather than chemical metallurgy. In contrast, the CVD method induces a strong metallurgical bond between titanium and diamond at higher temperatures, potentially damaging the diamond.

Processing methods for thick film diamond tools include mechanical grinding, hot metal disk grinding, ion beam etching, laser beam cutting, and plasma etching.

Diamond thick films are processed into grains averaging 32 to 37 μm in size through rolling grinding or produced directly via high temperature and pressure. This grain powder is then layered on WC-16 wt% Co alloy, isolated with tantalum foil, and sintered at 5.5 GPa and 1500 °C for 60 minutes to create a diamond sintered body. Tools crafted from this sintered material exhibit exceptional wear resistance.

A single crystal diamond tool fixes the diamond single crystal onto a small cutter head, which is then attached to the turning tool arbor using screws or pressure plates. The primary methods to secure the diamond to the cutter head include mechanical reinforcement (smoothing the diamond's bottom and pressure surfaces for attachment), powder metallurgy (sintering diamond within alloy powder in vacuum under pressure), and bonding or brazing techniques using adhesives. However, disparities in thermal expansion between diamond and substrate often lead to loosening and detachment of the diamond.

Previous: Ultra-Precision Diamond Tools: Everything You Need to Know

Next: None

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )